Active research partner

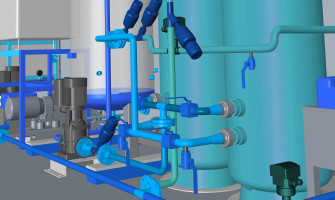

We at Andreas Junghans Filtration Technology® have already designed and built sophisticated special plants for research based on our process engineering plant concept. As plant developers, we integrate research topics into plant concepts and implement them in the research projects.

We have already implemented a wide variety of plants with many partners from the fields of industry and research. Processes such as organophilic nanofiltration, membrane extraction and pervaporation have been used.

Procedure list

-

Mexem

Ceramic Membrane Extraction systemsand adaptedelectrochemicalprocesses for the recovery of Metallicraw materials from low-concentration solutions

- Recovery of strategic metals (gallium, indium, possibly tellurium, vanadium, antimony) from process waters and tailings by a combination of membrane extraction and electrochemical separation

-

ESIMEM

Energy-efficient Separation of substances in the chemical and pharmaceutical Industry using membrane processes

- Energy saving in the chemical and pharmaceutical industry

- Supports the introduction of membrane technology organophilic nanofiltration (evaluation of this technology in early process development)

- Development of a systematic evaluation method for determining the separation properties of a membrane and tools for designing and calculating costs (allow comparison of OSN to other processes)

-

DCM²

Dehydration of critical Mixture using Membranes

- Development of membrane-supported, efficient dehydration processes for mixtures of supercritical CO² and organic solvents under high-pressure conditions from 40 bar to 100 bar

- Development and testing of advanced membranes, the associated membrane modules, the dewatering process and integration into the supercritical drying process

-

PAkmem

Effective treatment of problematic process and wastewater with ceramic nanofiltration membranes

- Development of integrated water treatment processes for process water containing salts and organic substances, using the example of wastewater from the oilgas and ceramics industries (nanofiltration)

-

KerWas

Thin-walled, ceramic membranes of adapted wettability and high volume-specific membrane surface for nanofiltration and membrane distillation for sustainable treatment of saline water

- Development and testing of thin-walled, ceramic membranes (adapted wettability and high volume-specific membrane surface) for sustainable treatment of mining wastewater by nanofiltration and membrane distillation

- Efficient treatment of saline wastewater

- Complete desalination for the preparation of boiler feed water via potable water treatment to the desalination of waste liquor under environmental aspects