Use of nanofiltration for best product quality

High-purity starting materials and products play a key role in the pharmaceutical industry, where legal standards and requirements are set particularly high. Reverse osmosis and nanofiltration are commonly used to remove impurities.

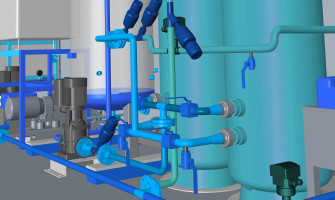

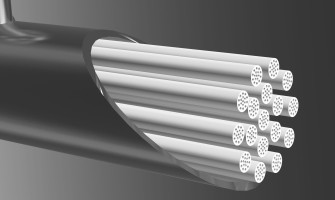

From the very beginning, our plants utilise the advantages of ceramic metal oxide membranes, which also meet the requirements for pure surface processing and sterility. In addition, our membrane plants with stainless steel components offer high chemical and thermal stability. This means the application can be flexible and chemical interactions cannot occur. Stainless steel processing and construction are carried out at pharmaceutical level and meet all legal standards for use in production.

As a research and development partner, we also offer micro and experimental plants as well as the leasing of plant technology.

Your advantages at

a glance

- Meets the legal requirements for sterile use in production

- Processing at standardised pharmaceutical level

- High thermal and chemical stability for flexible use without permanent chemical changes

- Long-term durability through robust components

- Easy sterilizability due to detergent-resistant materials

- High and constant performance due to cross-flow design

- Scaling according to your needs

- Manufacturer with over 20 years of experience in the design and manufacture of membrane plants

Applications

Membrane plants are very versatile. The following list therefore contains only some of possible fields of application in the pharmaceutical industry.

- Active ingredient enrichment

- Sterilisation of water and water mixtures (cold sterilisation)

- Water pre-treatment and recirculation

- Separation of organic solutions

Contact Us

We would be happy to advise you and develop the best solution for your separation project with you.